-

+86 0755-89302056

+86 0755-89302056 -

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

Cover plate laser automatic welding assembly production line

Square aluminum-shell battery cells are more in line with the technical requirements of automobiles because of their capacity, uniformity of performance and safety of use. Therefore, currently, new energy vehicles generally use their cells to form power battery packs to provide electric energy. Large single cells In addition to the chemical factors of its materials, the safety also has a lot to do with its design structure. The explosion-proof valve and flip piece on the cover plate used by the square aluminum shell battery are to improve its safety performance, and its welding process is even more important for the battery. Difficulties in welding.

In order to improve the quality level of products, battery cell manufacturers continue to improve the performance of production equipment. The automatic cover welding production line launched this time is to adapt to the needs of current market development. Its design modules include automatic loading and unloading, explosion-proof valve welding workstations, Cover accessories assembly, visual inspection, pole riveting, pole welding, helium inspection and NG classification marking and other stations as well as four galvanometer laser welding machines!

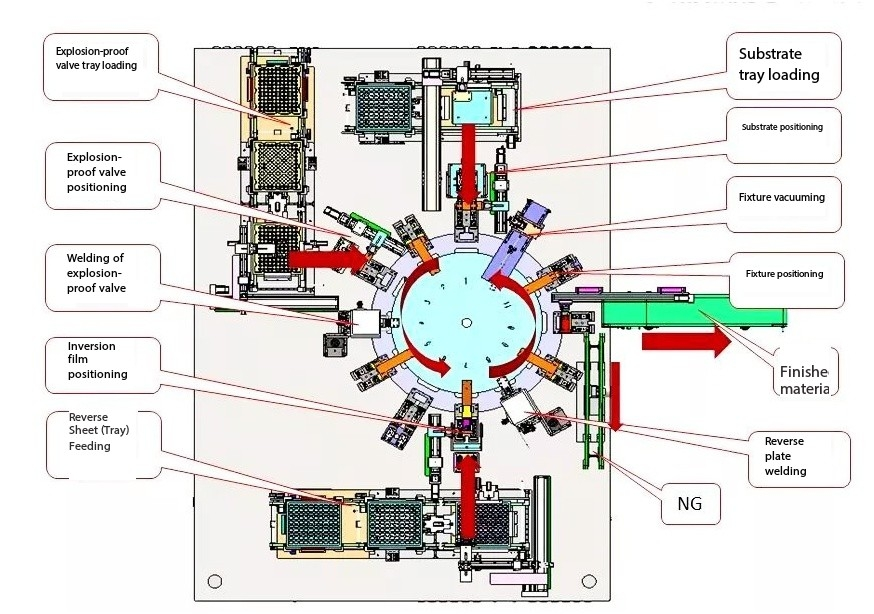

The cover plate automatic assembly line diagram is as shown below:

The automatic production line of cover plate—explosion-proof valve and flip piece welding module is as shown below:

SHINHOP laser equipment manufacturer has been engaged in the research and development of battery welding technology equipment. It has experience in the design of various types of battery laser welding automation, and is highly modular and practical!

[The above solutions are compiled from the Internet and are only for users to learn from. For actual solutions, you need to contact SHINHOP]

Tel:+86 0755-89302056

+86 0755-85200585

Address:Building 6, Jingneng science and technology environmental protection industrial park, No.3, Baolong Second Road, Longgang District. Shenzhen.China