-

+86 0755-89302056

+86 0755-89302056 -

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

How to make laser welding of battery explosion-proof valves better!

What is the function of a battery explosion-proof valve? Why does welding need to use laser? With these questions, let's first understand what a battery explosion-proof valve is.

First of all, we often see a slightly protruding position in the middle of the square aluminum shell battery cover. It is the thin-walled valve body of the battery sealing plate. Its main function is to prevent the internal pressure of the battery cell from being too high. This can be broken through first. The metal skin on the surface of the valve body prevents the battery from exploding. Its shape is often oval or round, and the structure is clever. Each battery cell accessories manufacturer has its own design method and patent. The material is basically two layers of solid aluminum plates. , its tensile strength cannot be higher than the material of the battery shell during welding, but it must be higher than the fracture pressure at the groove position of the explosion-proof aluminum plate, and it must be sealed and welded. The welding is difficult, and laser welding is required to meet its details. Process requirements.

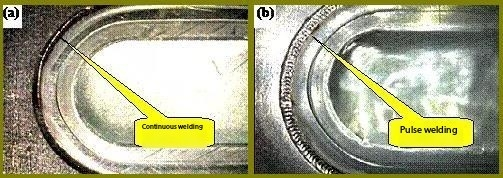

Laser welding of explosion-proof valves can use two methods: continuous welding and pulse welding. Relatively speaking, pulse valve welding requires overlapping welding points for sealing welding. However, the welding efficiency is poor, and the parameters set for pulse welding are more complicated. It is not easy to crack, and continuous welding requires higher assembly accuracy, which can ensure its welding efficiency compared with picks. However, due to the higher assembly accuracy of butt welding, it is sometimes difficult to ensure the consistency of welding. Here, Shinhop R&D Another efficient welding method is to use a single-mode fiber laser combined with a swing welding system, which can effectively redundant the non-uniform distance between work pieces. The power can be selected in the range of 500W-1000W to ensure Good welding quality, and improve the user's welding efficiency. For example, using a 1000W continuous laser to weld a 25X15mm explosion-proof valve only takes less than 2S of welding time, while using a normal welding test requires more than 10S, which shows the huge gap.

Tel:+86 0755-89302056

+86 0755-85200585

Address:Building 6, Jingneng science and technology environmental protection industrial park, No.3, Baolong Second Road, Longgang District. Shenzhen.China