laser welding machine, cutting machine, marking machine manufacturer

-

+86 0755-89302056

+86 0755-89302056 -

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

The importance of welding vision positioning system in laser welding

The laser visual positioning system is the "icing on the cake" in laser processing equipment. For users with high-precision welding requirements, visual positioning is very important, especially those engaged in the welding and manufacturing process of battery cells and power batteries. With the visual positioning system, it The quality of the welding process can be significantly improved, which will greatly help the safety and quality of the battery.

The laser CCD visual welding positioning system can automatically identify incoming work pieces, distinguish the welding areas of different work pieces, and help automatically and accurately search and find the preset welding area of each work piece. After automatic and accurate positioning, the welding position can be output in real time through data communication coordinates to guide the laser for precise welding on the preset trajectory.

The laser vision system can also use software to recheck the size, position and appearance of the welding trace after the welding is completed. And realize the actual monitoring of welding quality during the production process, thus greatly improving the production yield.

Working principle of laser vision welding positioning system:

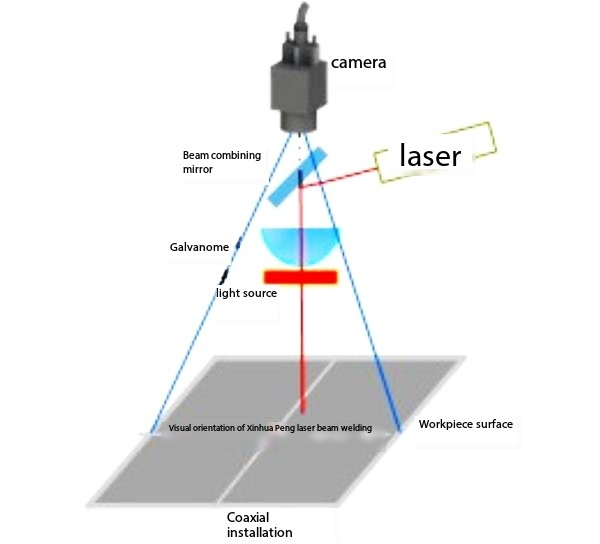

The laser vision welding positioning system consists of three parts: the vision system, the motion mechanism and the laser welding system. The connection system is established through visual calibration. The calibration is divided into two parts.

One is divided into the vision system and the laser welding system. The vision system coordinate system and the laser welding coordinate system are calibrated through a high-precision nine-point punctuation algorithm.

The other part is the coordinate system calibration of the welding head door of the vision system and motion mechanism.

In actual welding production, the steps are as follows

1. First calculate the welding position and angle, and then send the offset to the kinematic mechanism;

2. The motion system uses position offset to adjust the position of the welding head;

3. The laser vision welding system uses the position and angle offset to adjust the welding pattern to weld the precise position;

4. The laser vision welding positioning system uses a geometric contour matching positioning algorithm in the positioning calculation process. The repeated positioning accuracy is 140 sub-pixels and is not interfered by uneven light. For areas that are significantly affected by light, the visual positioning system can add supplementary The light source is provided in the form of light, and red light is generally used to supplement the light to improve the accuracy of visual positioning;

5. Combined with line-finding tools, various features can be easily prepared and located;

Tel:+86 0755-89302056

+86 0755-85200585

Address:Building 6, Jingneng science and technology environmental protection industrial park, No.3, Baolong Second Road, Longgang District. Shenzhen.China