laser welding machine, cutting machine, marking machine manufacturer

-

+86 0755-89302056

+86 0755-89302056 -

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

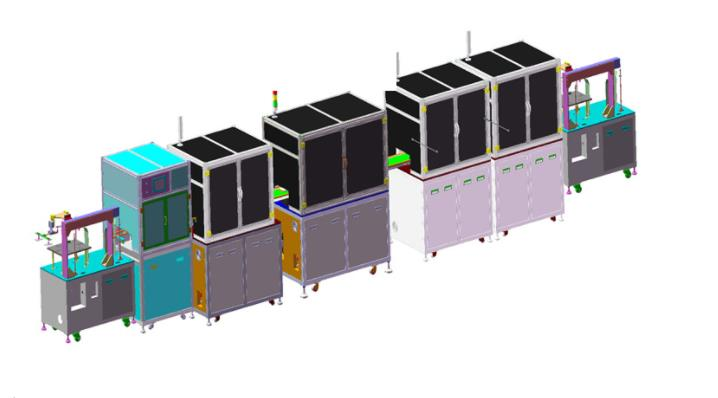

Automatic welding assembly line for Pouch cell and modules!

SHINHOP battery laser welding solution provider provides users with automated assembly lines for Pouch cell and modules, providing users with better Pouch battery core welding and assembly solutions to improve product quality, safety and production efficiency.

Streamlined Pouch cell tab automatic welding line:

1. Nickel strip/battery core loading and unloading:

Pouch cell can be added to the loading platform in a stacked manner, and the batteries are sucked by a pneumatic device to realize loading to the assembly line. The nickel strip is rotated and transported by a winding disk, and reaches the welding station for automatic cutting;

2. The purpose of X-ray testing is to detect the parallelism of the polar bands;

3. Polar band shaping;

4. The visual monitoring system can monitor the position of the battery core and the status when it is fixed to the tab in real time, and whether it meets the welding prerequisites;

5. Four/six-station rotating disc;

6. The pole bending mechanism;

7. The welding quality inspection agency will classify the cells whose welding quality does not meet the technical process;

8. The unloading mechanism automatically unloads the welded battery cores.

2. Pouch package PACK automatic assembly line:

1. Automatic cell code scanning, cell OCV/IR detection; tab leveling, aluminum-plastic film insulation resistance test;

2. Automatic tab cutting, tab bending, and tab plasma cleaning;

3. Stack the battery modules and install the fixing bolts;

4. Battery module flipping, manual installation of welding plates, and pre-bending of tabs;

5. Bending of pole ears;

6. The pole lug automatically rolls flat;

7. Automatic laser welding station;

8. Automatic EOL testing;

9. Manual cutting;

[Remarks: All configurations need to be customized according to the user's product process requirements. Modules are added or deleted, and there is no standard configuration]

Tel:+86 0755-89302056

+86 0755-85200585

Address:Building 6, Jingneng science and technology environmental protection industrial park, No.3, Baolong Second Road, Longgang District. Shenzhen.China