laser welding machine, cutting machine, marking machine manufacturer

-

+86 0755-89302056

+86 0755-89302056 -

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

Why is plasma cleaning required during laser welding of power battery cells?

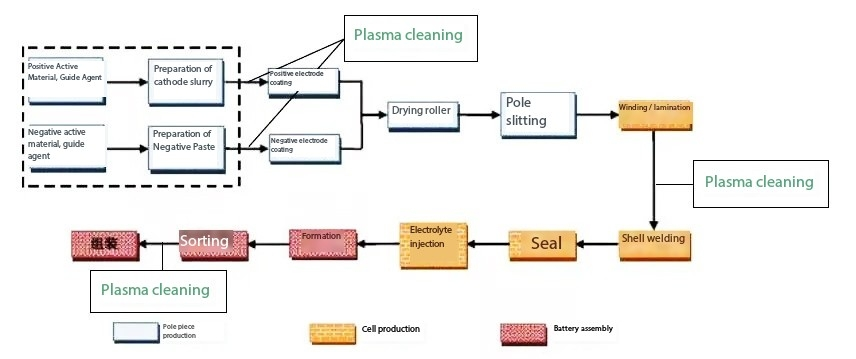

Power battery packs need to be charged and discharged frequently, so the reliability of their products must be high. They must discharge stably and ensure that the welding wires do not corrode or fall off. Especially for battery systems used in transportation, more attention must be paid to the battery. Regarding the reliability of welding quality, the plasma cleaning system we talked about today actually cleans the welded parts before battery welding to increase the welding adhesion and make it stronger and more reliable. Therefore, we can summarize the application of plasma cleaning for battery module welding into three key reasons!

1. When performing automatic assembly and welding of power battery modules, the cells need to be cleaned, especially after edge sealing or tab leveling. Plasma cleaning can remove impurities such as organic matter and small particles and improve the reliability of laser welding.

2. welding of the positive and negative poles of the battery is required. The poles are metal strips that lead out the positive and negative poles from the battery core. Generally speaking, the ears of the positive and negative poles of the battery are the contact points during charging and discharging. This contact point Whether the surface is clean will affect the reliability and durability of the electrical connection.

3. Plasma cleaning is required when the module end plate and side welding are assembled. This not only prevents small particles such as dust from entering the interior of the battery module, but also improves the reliability of the laser seam welding of the side plate and end plate.

Laser cleaning machines play a role in fine processing during module assembly. They may not seem to have much effect, but they can often lead to quality and safety problems for the entire battery module. Therefore, as a manufacturer of laser welding production equipment for power battery modules, When handling these details, we must provide users with reasonable technical support and configuration. We must not ignore user quality assurance in order to lower prices to obtain user orders. Users must not ignore the performance value of the equipment itself because of high prices.

Tel:+86 0755-89302056

+86 0755-85200585

Address:Building 6, Jingneng science and technology environmental protection industrial park, No.3, Baolong Second Road, Longgang District. Shenzhen.China