-

+86 0755-89302056

+86 0755-89302056 -

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

Building 6, Jingneng science and technology environmental protection industrial park, No. 3, Baolong Second Road, Longgang District

Product Details

System specification:

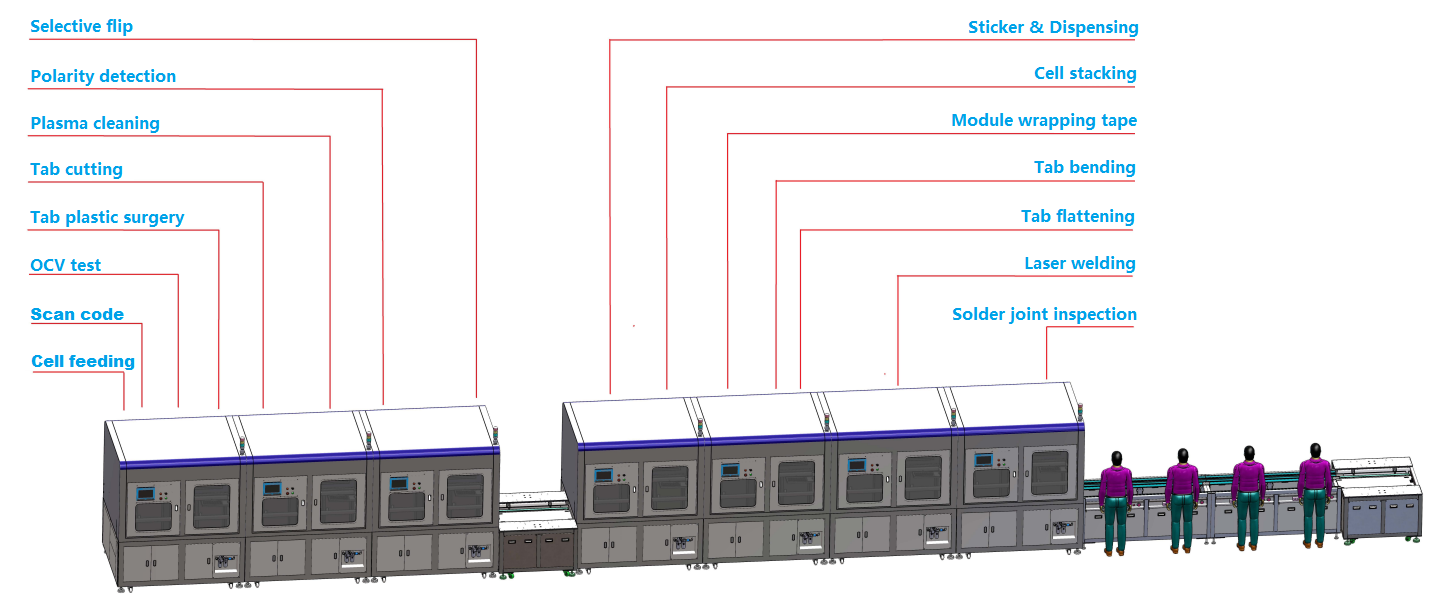

This production line includes three parts: soft-packed battery core processing, module molding and welding, and PACK assembly. It involves many subsystem module configurations, such as tab cutting and bending stations, unit assembly lines, laser welding lines, manual/ Automatic module assembly line, manual/automatic PACK assembly line, laser host, laser welding visual positioning system, welding quality inspection system, etc.

Features:

1. Equipped with production robots and automation equipment to realize automatic loading and unloading, suitable for the welding production of soft pack battery modules of various specifications;

2. Cutting and bending of battery tabs, automatically matching the bending and cutting ratio according to production tasks;

3. Manual/automatic overlay module;

4. Manual/automatic assembly of PACK;

5. Realize automatic post-weld quality inspection;

5. Equipped with a dust removal and cleaning system to ensure the cleanliness inside the machine;

6. Advanced MES management system enables traceability of welding production.

Basic parameters:

1. Applicable battery cell sizes: 80-250mm (W), 100-400mm (H), 2-25mm (T);

2. Welding position: ≤±0.3mm;

3. Parallel accuracy of two pole lugs: ≤±0.2mm;

4. The welding seam width and welding tension are in line with industry requirements;

5. Welding yield ≥99.8%

Tel:+86 0755-89302056

+86 0755-85200585

Address:Building 6, Jingneng science and technology environmental protection industrial park, No.3, Baolong Second Road, Longgang District. Shenzhen.China